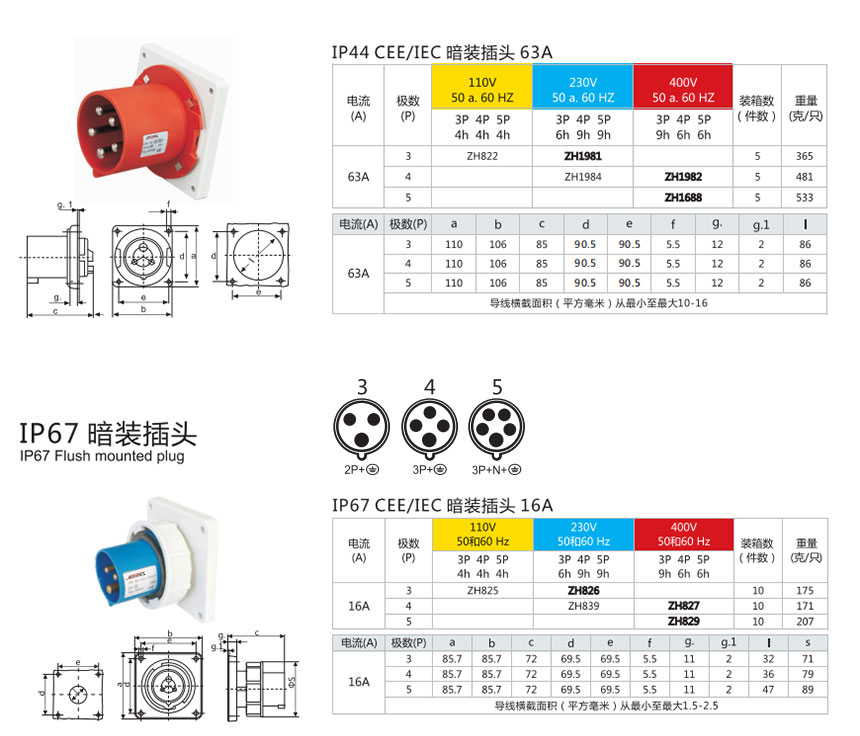

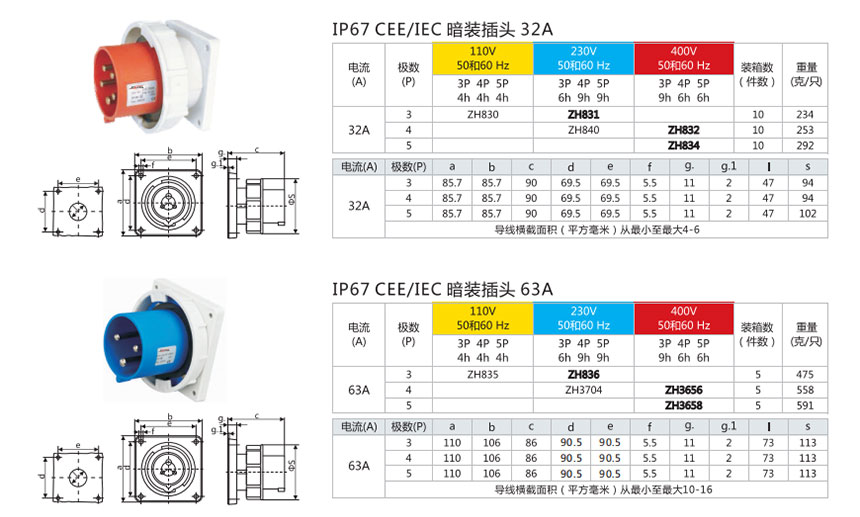

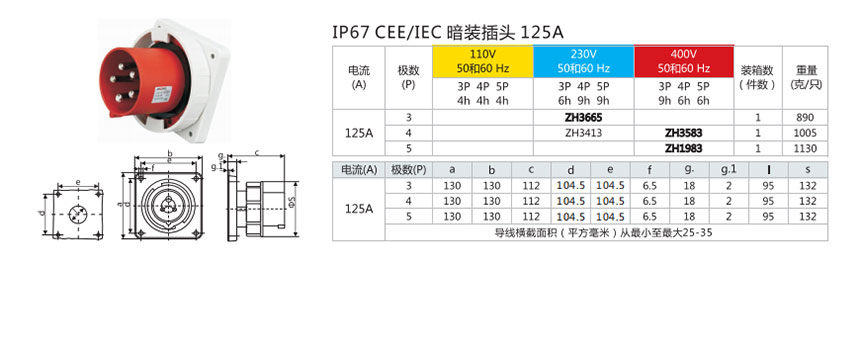

| Rated current | 16A/32A/63A/125A |

| Poles | 3P/4P/5P |

| Voltage | 200V-250V/380V-415V |

| Clock position | 6h |

| Hertz | 50-60Hz |

| Protection type | IP44/IP67 |

Panel-Mount Plugs are industrial-grade connectors designed for permanent power output or equipment-side power access, securely installed on equipment panels, cabinets, or distribution enclosures. Their primary function is to ensure safe and stable electrical transmission by interfacing securely with panel-mount sockets (e.g., IEC 60309-compliant sockets), while maintaining operational safety.

| Rated current | 16A/32A/63A/125A |

| Poles | 3P/4P/5P |

| Voltage | 200V-250V/380V-415V |

| Clock position | 6h |

| Hertz | 50-60Hz |

| Protection type | IP44/IP67 |

High Safety Performance

Water & Dust Resistance: IP67 or higher ingress protection ensures reliable operation in extreme environments, including heavy rain, dust, and oil contamination.

Shock Prevention: Recessed pin design and mechanical interlock mechanisms (requiring power disconnection before mating) minimize operational risks.

Flame Retardancy: PA6 (Polyamide 6) housing provides high-temperature resistance (-40°C to 125°C) and meets flame-retardant standards.

Durability & Reliability

Extended Mating Cycles: Nickel-plated high-quality copper alloy contacts support over 10,000 insertion/extraction cycles.

Mechanical Impact Resistance: Rugged construction withstands drops, compression, and frequent vibrations, making it ideal for demanding industrial applications (e.g., construction machinery).

Flexible Adaptability

Modular Design: Compatible with various cable configurations (e.g., 5-core cables for three-phase power + grounding + signal transmission).

Color Coding: Voltage differentiation via color-coded rings (e.g., yellow for 110V, blue for 230V) prevents mismating errors.

Efficient Maintenance

Tool-Free Installation: Enables quick installation without tools, significantly reducing equipment downtime.

Low Failure Rate: Integrated sealing technology minimizes issues such as poor contact and short circuits.

Structural design

Pin layout: Asymmetric design (such as 3P+E) is adopted to ensure the only insertion direction.

Sealing structure: Rubber sealing ring + thread locking to achieve double waterproofing.

Application Scenario

Heavy industry: port cranes, welding equipment, automated production lines.

Outdoor scenes: stage lighting, temporary power supply stations, new energy charging piles