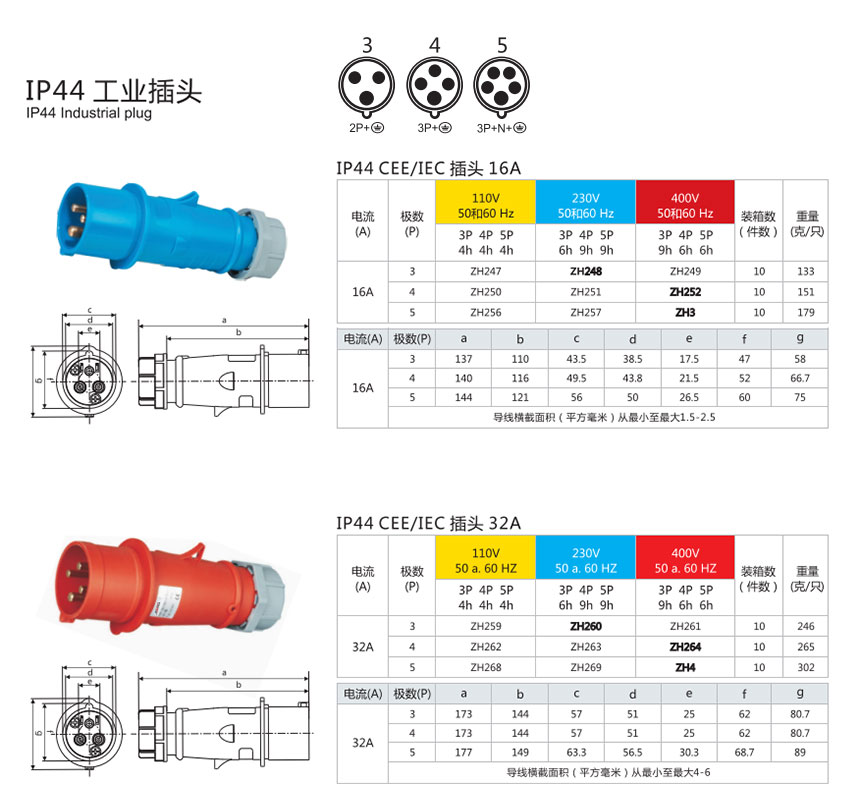

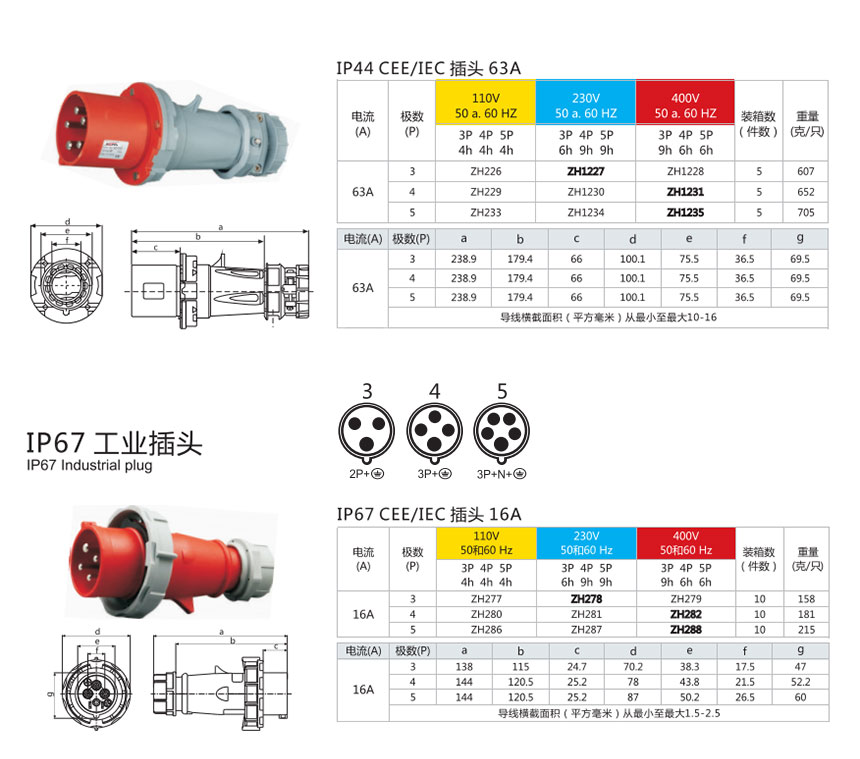

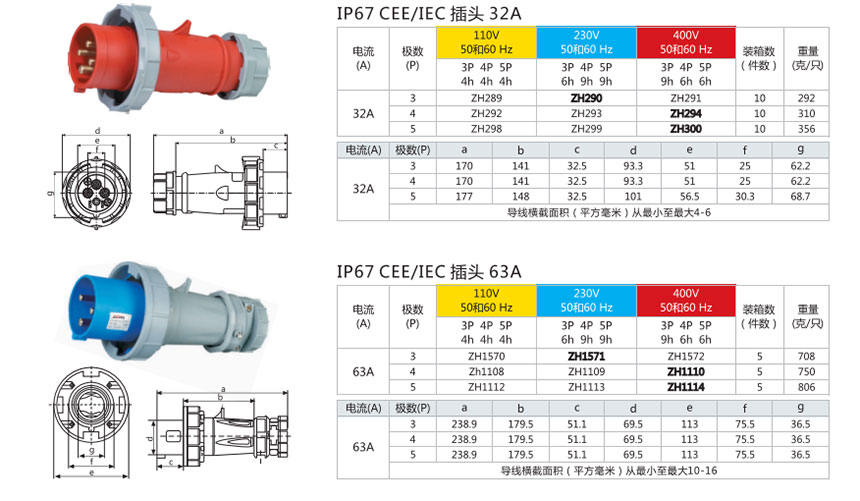

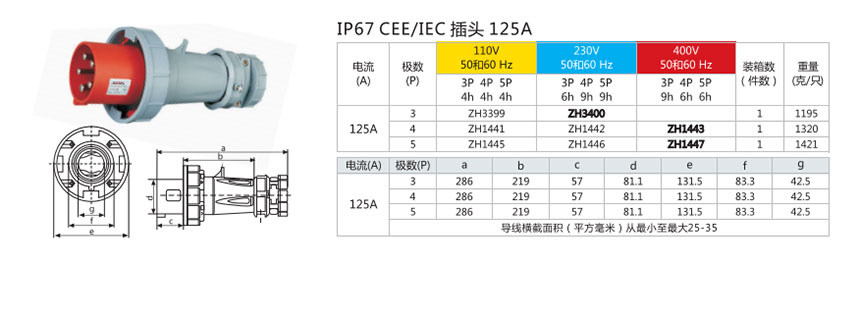

| Rated current | 16A/32A/63A/125A |

| Poles | 3P/4P/5P |

| Voltage | 200V-250V/380V-415V |

| Clock position | 6h |

| Hertz | 50-60Hz |

| Protection type | IP44/IP67 |

Industrial plugs and sockets (Industrial Plug & Socket) are high-performance electrical connection devices specifically engineered for industrial environments, designed to safely transmit electrical power or signals under harsh operating conditions. Compared to standard household plugs, industrial-grade connectors demonstrate superior load-bearing capacity, enhanced protection ratings (IP codes), and exceptional durability. These robust components find extensive applications across multiple sectors including manufacturing industries, energy infrastructure, construction projects, port facilities, and stage/theatrical equipment installations.

| Rated current | 16A/32A/63A/125A |

| Poles | 3P/4P/5P |

| Voltage | 200V-250V/380V-415V |

| Clock position | 6h |

| Hertz | 50-60Hz |

| Protection type | IP44/IP67 |

High Operational Safety

Water & Dust Resistance: IP67 or higher ingress protection ensures reliable performance in extreme conditions including heavy rainfall, dust-laden atmospheres, and oil-contaminated environments.

Shock Prevention: Recessed pin configuration and mechanical interlock mechanisms (mandating power disconnection before operation) minimize electrical hazard risks.

Flame Retardancy: PA6 (Polyamide 6) housing demonstrates exceptional thermal stability (-40°C to 125°C)

Durability & Reliability

Extended Mating Cycles: High-grade nickel-plated copper alloy contacts ensure over 10,000 insertion/extraction cycles with minimal wear.

Mechanical Resilience: Impact-resistant construction withstands frequent vibration and mechanical shocks in demanding applications (e.g., construction machinery, heavy-duty equipment).

Adaptive Flexibility

Modular Architecture: Compatible with multi-core cables (e.g., 5-core configurations for three-phase power + grounding + signal transmission).

Color-Coded Identification: Voltage differentiation via color-coded rings (e.g., yellow for 110V, blue for 230V) prevents mismating errors.

Maintenance Efficiency

Tool-Free Installation: Tool-free installation capability enables rapid deployment, significantly reducing equipment downtime during maintenance.

Structural design

Pin layout: Asymmetric design (such as 3P+E) is adopted to ensure the only insertion direction.

Sealing structure: Rubber sealing ring + thread locking to achieve double waterproofing.

Application Scenario

Heavy industry: port cranes, welding equipment, automated production lines.

Outdoor scenes: stage lighting, temporary power supply stations, new energy charging piles